INTRODUCTION

Gabion retaining walls are structures made by stacking wire baskets filled with rocks or other materials. These walls are commonly used in civil engineering and landscaping to stabilize slopes, prevent erosion, and create terraced structures. Gabion is a wire fabric container, which is systematically partitioned with variable size units, interconnected with other similar containers and filled with suitable stones at the site of use to form flexible, permeable and monolithic structures and serve the purpose of retaining walls as well as other uses, like sea walls, channel lining, revetments and wires.

A gabion retaining wall is a gravity retaining structure and retains soil with its weight and section. These are extensively used in hill infrastructures as a toe support for cut slopes and natural slopes. The high porosity and permeability of gabions prevent the pore-water pressure development behind the walls, which is a major advantage here. Unlike walls made of rigid structures, such as cement stone masonry and RCC, gabion walls have the advantage of being able to withstand large deformations without cracking and are flexible. These structures blend with the surroundings and allow vegetation to take roots through the structure, which enhances the life of the structure.

The gabion walls are suitable in various field conditions, particularly where the terrains are liable to become saturated and where the foundation is composed of relatively compressible materials like debris and other unconsolidated materials. Hence, gabion walls are widely used in rugged hilly terrains. Gabion walls are relatively simple to construct. Where suitable rock blocks are readily available as fill material, the use of gabion walls is particularly attractive for reasons of economy and speed of construction. Keeping this in view, effective utilization of gabions has been adopted in many of the infrastructures like highways, railways, bridges, road structures, river front structures, bridge abutments, culvert protection works and in a number of other uses. This article particularly deals with its utilization as a retaining wall at the toe of cut slopes and natural slopes.

Construction of Gabion Retaining Walls

MAIN COMPONENTS OF GABION RETAINING WALL

Gabion retaining wall is a gravity structure, made up of row upon row of orthogonal cages or baskets of varying sizes, which are filled with rock blocks and tied together. Gabion walls have three major components namely gabion box, stone for filling gabion and backfill.

Gabion Box

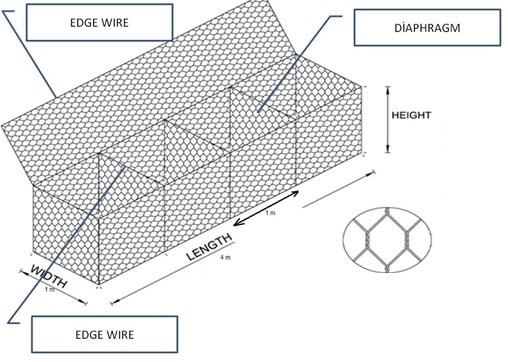

It is a rectangular box fabricated using heavily galvanized and double twisted steel woven wire mesh. Steel woven wire mesh is common for retaining wall purposes. The box is divided into cells by transverse diaphragms. For using the gabions in harsh and aggressive environments additional PVC coating is done over the heavily galvanized steel wire. Nylon, polypropylene and polyethylene materials may be used in specific conditions.

Gabions are manufactured with all components mechanically connected at the production facility. The external face and top lid are made from the same mesh. The ends, back, and diaphragm are connected to the base at the installation site by helical wires or other methods. All perimeter edges of the mesh forming the basket have selvedge with wires having diameter of about 1.5 times that of the wire-mesh to prevent unravelling. The gabion base, top and sides should be formed from a single piece of mesh. The completely woven wire mesh box can stretch or contract in two directions in its own plane and thus a rectangular wire mesh basket filled with rock blocks can deform in any direction. Welded wire-mesh is also manufactured from steel wire electrically welded at each intersection. It does not have the ability to stretch and contract so that the baskets are less flexible as compared to woven wire-mesh gabions. Gabions are supplied to project site from factory with its components folded flat, collapsed

and packed in bundles.

A variety of cage sizes are used taking into account the availability of materials and to suit the terrain. However, the modules of 2 m × 1 m × 1 m with 2 m being parallel to the hill face is the commonly adopted gabions size in the hills. The above type of simple boxes are used for gabion walls up to 6 m height. However, if the walls are to be designed for more heights, strong boxes to withstand higher gravity loads are required. For that purpose, additional measures, such as bracing wire/stiffener as well as spenax fasteners/overlapping fasteners/steel rings can be provided in addition to other safety measures. Since low to medium height gabion walls are extensively constructed in hills for various purposes, this standard focuses on gabion walls up to 6m. If more height of the wall is required, a horizontal or inclined (up to 30°) bench/platform shall be provided at 6 m height having a bench width of 3 m. Further walls for more height can be planned safely by providing such benches.

Gabion infill Material

Rock blocks used for filling gabions should be fresh to fairly fresh, hard, angular to sub-rounded, durable, clean and well graded. Weathered rock bocks shall not be used as they tend to break under loading. Care should be taken to ensure good quality that they do not lose their integrity on exposure to atmosphere or water during the life of the structure. The maximum size of the rock block should not exceed two-thirds the depth of the gabion to be filled or 300 mm, whichever is less. The preferred size is 150 mm to 300 mm. The smallest dimension of the rock block should at least be twice the largest dimension of the mesh aperture.

Backfill

The hill cutting for Gabion wall construction is generally minimum particularly in case of low height walls (< 3 m). However, it may be considerable in case if the height of wall is more. If the width of the backfill is 0.5 m or more, the inverted filters is recommended here as back fill. If the width of the backfill is less than 0.5 m, free draining materials ranging from small boulders to coarse sand shall be dumped in the gap between the wall and hill cutting. In all cases of backfill, the top 0.5 m thickness shall be filled tightly with natural soil or impervious clayey soil to prevent ingress of surface water into the backfill material. The growth of vegetation on the top soil and penetrating roots through the structure of gabion in short time will help to blend it with the surroundings, which enhances the life of the structure.

DESIGN CONSIDERTIONS

The Gabion retaining walls up to 6 m height can be designed as unreinforced gravity retaining walls with the following general design consideration, which is found to be adequate based on preliminary analysis:

a) Top width — 0.75 m to 1.0 m, and

b) Base width — 0.6 to 0.75 H (H = height of wall).

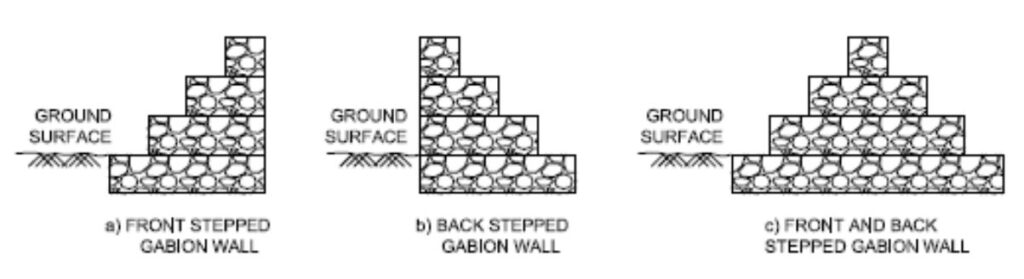

The Gabion retaining wall is constructed by placing gabion boxes systematically one over the other covering the entire length of the slope to be protected. The placement of the boxes can be generally done in three patterns – front stepped wall, back stepped wall as well as front and back stepped wall. It may be better if the walls are provided with a back batter (that is, having dip towards valley) of about 6 : 1 to 10 : 1. The base of the wall should be embedded to a depth of 0.5 m to 0.75 m into the soil with increased depth in case of compressible type of soil. The front stepped gabion retaining wall with a batter of 6 : 1 is more preferred in hilly terrains in view of its high stability and ability to take more deformation.

CONSTRUCTION PRACTICE

Foundation Preparation

Construction of gabion retaining walls starts with foundation preparation. The foundation is excavated to the desired width and depth. Loose pockets if any, shall be excavated and filled back with suitable granular or backfill material. The place should be cleared of standing water to ensure proper placement of gabions. The entire surface should be compacted well so that the density of compacted formation should be greater than or equal to 95 percent of the modified Proctor value. Later the formation shall be levelled without ruts and undulations.

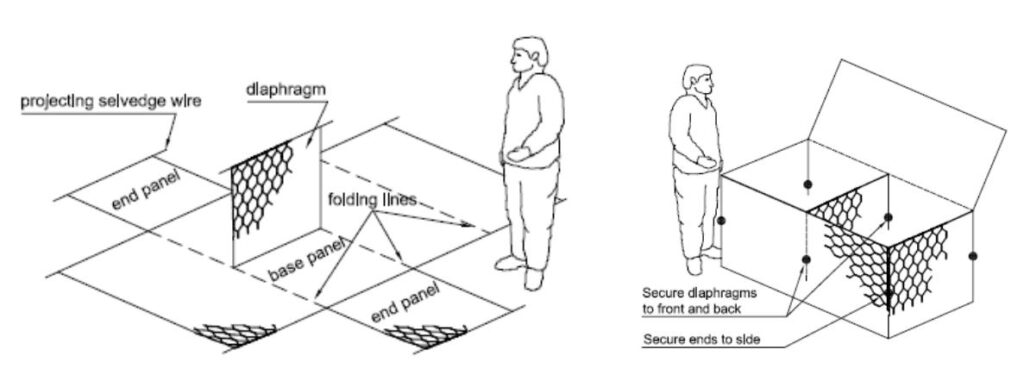

Installation of Gabion Box

The gabion panels are unfolded and laid over an even, levelled and hard surface. The side panels of hexagonal woven mesh gabions should be stretched taut by properly straightening them. The gabion boxes should be correctly assembled by folding the side panels and wiring them together so that all four corners match and form an exact rectangular shape and size as designed. The edges are laced together, starting from top corner and in a continuous operation using alternate single and double loop at the spacing of one mesh length. The ends of the lacing wire are secured at each corner. Individual ties of lacing wire should not be used. Alternatively, steel rings can be used which are attached using a mechanical tool. It should be ensured that the boundaries of all panels are suitably woven using the thick selvedge wires. Wherever possible, the vertical joints between the units should be staggered in adjacent courses to prevent the formation of weak vertical shear planes through the gabion wall and to give a better and more integral appearance.

Filling of Gabions

The gabions should be tightly filled to ensure minimum voids. For better finish, the stone fill of the front face is first selected and placed carefully to give the best appearance. When using quarried/crushed rock blocks, they shall be selected in such a way that at least one face is flat-shaped. Some overfilling is recommended to allow for subsequent settlement of the rock infill. Sharp particles in crushed rocks may cause damage to the wire-mesh of gabions or its protective coating. Therefore, strict supervision is required to ensure proper filling. After filling, the lids of the gabions are closed so that they meet the top edges of the sides and ends of the box without leaving any gap. The mesh lids should be tied down to the tops of diaphragms provided as well as to the tops of the sides and ends. Facia of adjoining units shall be securely joined together along the vertical facing and top edges of their contact surfaces.

Other boxes in the rows above are also placed and packed in position following the same procedure to complete the wall.

Porosity Check

The average porosity of the gabion boxes can be found out by weighing the filled boxes. The weight of the box can be compared with calculated weight of box. Assume the density of the stone (rs) = 26 kN/m3.

In general, porosity (n) of the filled gabion box shall be around 30 to 40 percent

Density of gabion would be rg = rs × (1 – n) ignoring air voids

Assuming 35 percent porosity the density of gabion = 16.9 kN/m3.

Hence, weight of 1.5 m × 1 m × 1 m Gabion box = 1.5 × 16.9 = 25.35 kN ~ 2.5 ton

The weight of the filled gabion box should be approximately equal to the calculated weight.

Back-filling Behind Gabions

The inverted filter material as specified by relevent codes shall be used as back-fill behind the gabion

wall. This shall be achieved by placing materials of desired sizes and compacting them in layers of 200 mm to 300 mm up to the top. However, in order to prevent the seepage of surface water into the backfill material, the top 500 mm shall be packed with natural soil or impervious clayey soil.

2 thoughts on “Construction of Gabion Retaining Walls”